Dental Milling Applications Overview

Milling is used extensively in dental manufacturing. It works well with many different materials like zirconia, e-max, PMMA, acrylic, cobalt-chrome, titanium and stainless steel.

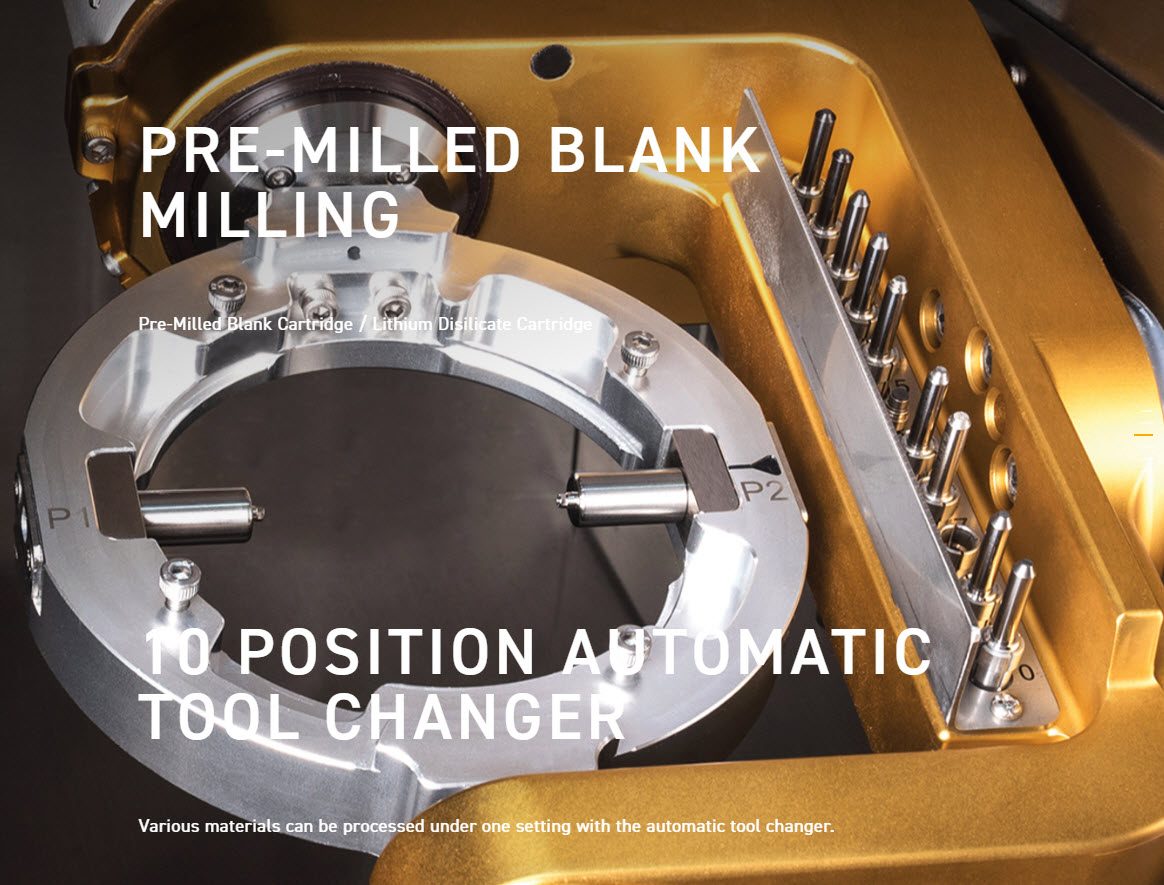

Milling is very accurate and fast but you need the right type of CNC machine and very good CAM software to get a good result. The CNC machines available are operating in either 3, 4 or 5 axis. The type chosen depends on the type of work you do. For simple crown & bridge work you can get away with a 4-axis machine but for milling undercuts and angled implant holes you will need a 5-axis CNC machine and a capable 5-axis CAM software to go with it. The capabilities and ease of use can vary a lot from one software to another.

Typical milling applications are crown & bridge, implants, implant dentures, abutments, dental bars, bite splints and full dentures.

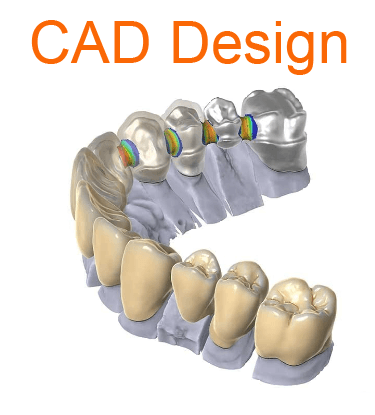

Crown & Bridge Applications

Milling crown & bridge restorations in zirconia and e-max materials is in volume the dominant dental milling application. You will need an accurate machine for milling soft materials. Most zirconia milling is done dry with a dust suction unit. Alternatively zirconia can be milled wet with circulating water that can give a better surface finish but there is a risk the water can discolour the zirconia.

Litium Disilicate Glass Ceramic materials like E-max materials are usually cut wet from a small single unit block. Lithum Disilicate materials are well known for their excellent aesthetic properties, strength and good bonding properties.

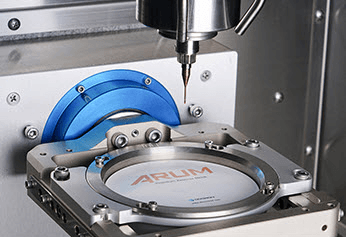

Suitable Arum machines:

Arum Mill 5X-400 Arum Mill 4X-300 Arum Mill 5X-300

Upcera A53 24-disc

Bite Splint Applications

Bite splints are ideally made in acrylic or PMMA materials. exocad dental design software has an excellent Splint module for designing splints.

The splint is designed from an impression or an intra oral scan and only takes about 10 minutes to finish. CNC milling can be performed in a 4 or 5-axis mill but a 5-axis is preferred.

Suitable Arum machines:

Full Denture Applications

Full Dentures can be made in pink PMMA or similar materials. exocad dental design software has an excellent Full Denture module for designing dentures.

The denture base with teeeth is designed from an impression or an intra oral scan and only takes about 20 minutes to finish. CNC milling can be performed in a 5-axis mill. The teeth are designed from a library in the Full Denture module and subtracted from the denture base to form the cavities for each individual tooth. Manufacturing of the teeth can be done with milling, 3D printing or using pre-fabricated teeth from a supplier.

Suitable Arum machines:

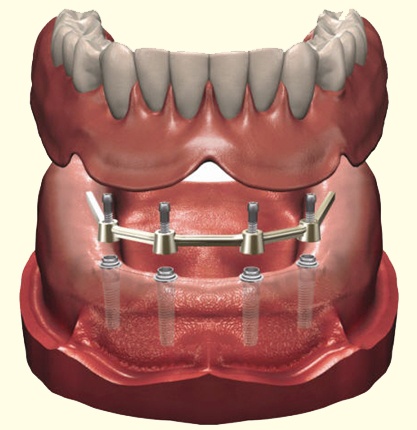

Dental Bars and Custom Abutments

Dental Bars are generally made in metal, titanium or cobalt-chrome.

The dental bar is designed from an impression or an intra oral scan with implants in exocad Dental Bar Module and only takes about 20 minutes to finish.

For milling the bar you will require a metal cutting 5-axis CNC mill. This is a far more robust mill than one required for cutting zirconia restorations. The cutting process is more complicated because we are cutting metal using small cutters. A lot of the complications are handled by pre-programmed milling templates that controls the cutting process.

Suitable Arum machines: